SM1000/P20

The SM1000/P20 is a specialized blast cabinet fitted with a certified pressure vessel, making it ideal for aggressive blasting and cleaning.

Suitable for cleaning corroded steel components and creating a surface profile.

Specifications & Size

Length: 1000 mm

Depth: 850 mm

Height: 1850 mm

Internal height (including turntable): 800 mm

Air consumption: 2350 LPM | 84 CFM at 6 Bar

Light: 220 V

Weight: 276 kg

*Comes complete with Standard Venturi Nozzle (6mm)

Advantages

Aggressive

Fitted with a certified 20L pressure pot, the SM1000/P20 is ideal for aggressive industrial blasting and cleaning.

Practical

Fitted with two doors for easy loading and internal fluorescent lights for visibility.

Fast

Ideal for cleaning C and D rust-graded steel. 8-10 times faster than traditional suction cabinets.

Manageable workspace

The SM1000\P20 comes standard with a fitted turntable, assisting the blasting of larger components.

Durable and robust

The SM1000/P20 is urethane-lined for greater wear-resistance. A stainless steel mesh provides extra protection for its glass window

Ideal for steel abrasives (steel grit or shot)

Complete with a 6.5mm venturi blast nozzle

Components

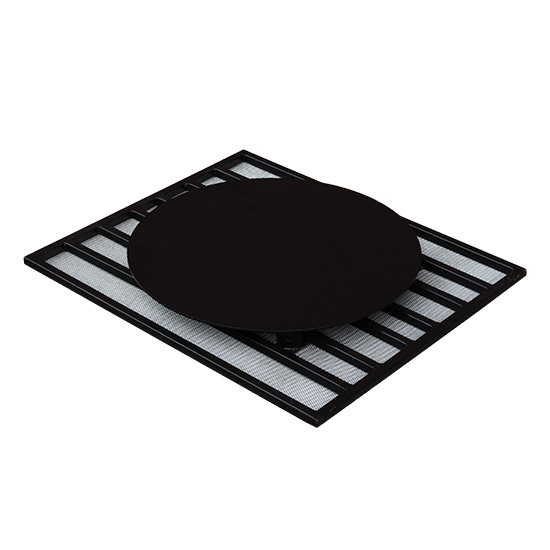

Turntable

The SM1000/P20 comes standard with a turntable making it easier to manoeuvre and access parts during the cleaning process.

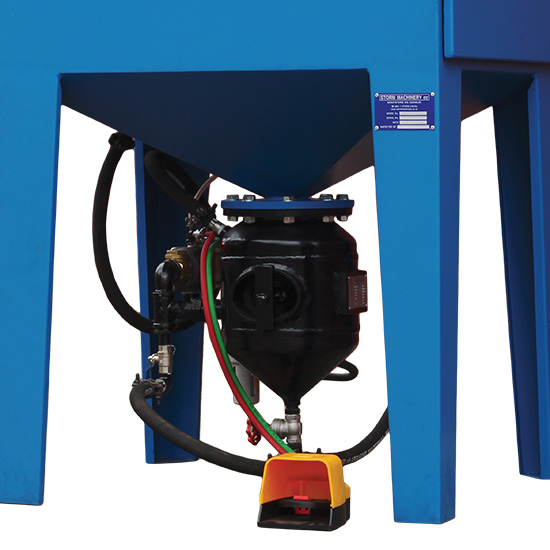

Certified 20L Pressure Vessel

A 20L certified pressure vessel facilitates the usage of steel abrasives, making the SM1000/P20 ideal for heavy duty cleaning and blasting. The pressure vessel is able to hold up to 50kg of steel shot or grit and is operated by a stop/start foot pedal.

Cyclone

When blasting with finer abrasives such as glass grit/beads, a cyclone pre-filter is required to help recover abrasives that can be recycled.